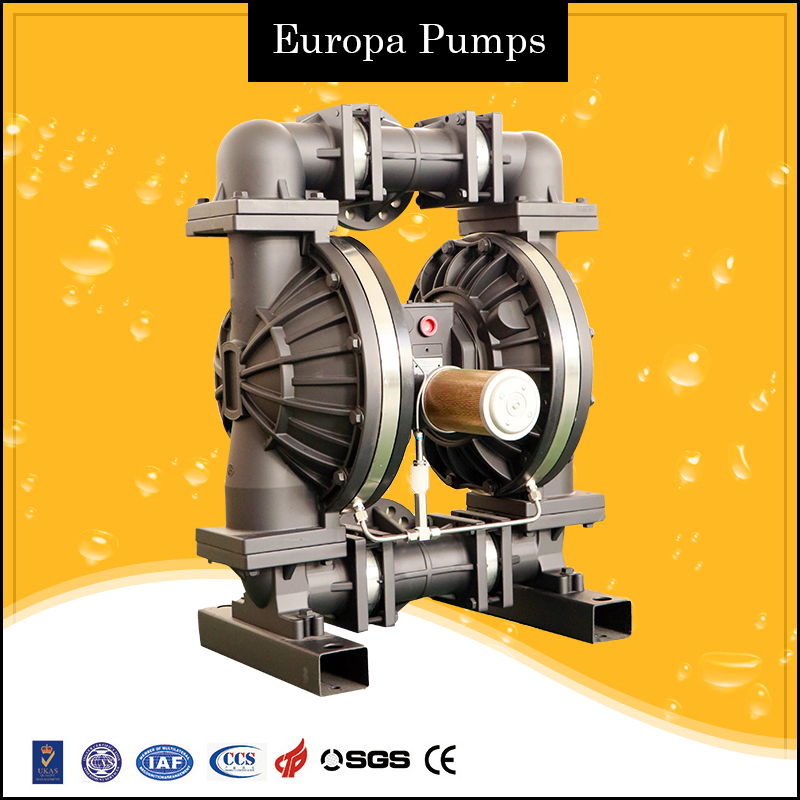

Double Diaphragm Pump

The Working Mechanism

We have a long and proud history givin emphasis to environment social and economic outcomes to deliver places that respond too the complex global forces shaping our future

The double diaphragm has positive displacement which utilizes two flexible diaphragms that reciprocate back and forth, creating a temporary chamber, which both draws in and expels fluid through the pump. The diaphragms work as a separation wall between the air and the liquid. Ceracin manufactures high-quality diaphragm pumps suitable to serve broader applications. The years of experience that we have to help us manufacture the best quality product which can stand through the toughest of weather. As a result, we are one of the top Double Diaphragm Pump Manufacturers.

Know More Features & Applications

Features

Our Pumps Comes With Exclusive Features!

- These pumps are essentially leak-free.

- There are only stationary seals between the wetted parts and the outside environment so leakage can only occur if one or both diaphragms fail.

- As part of a general maintenance programme, diaphragms should be replaced regularly, according to the manufacturer’s recommendations

Applications

Various Applications In Different Industries!

- Corrosive chemical

- Volatile solvents

- Viscous, sticky fluids, dirty water and abrasive slurry

- Shear-sensitive foodstuffs and pharma product

- Smaller solids & creams, gels and oils

Double Diaphragm Pump

The double diaphragm pump is a versatile workpiece that enables users across a hugely diverse range of industries to standardise on a single pump type for handling a wide variety of fluids.

We have a long and proud history givin emphasis to environment social and economic outcomes to deliver places that respond too the complex global forces shaping our future

Whether fluid being handled requires a gentle pumping action, is chemically or physically aggressive, the positive displacement AODD pump offers an efficient and low maintenance solution. Ceracin plays its role by effectively supplying these industry workhorses across different nations. Thanks to our robust supply chains we have become the top Double Diaphragm Pump Exporters In India.

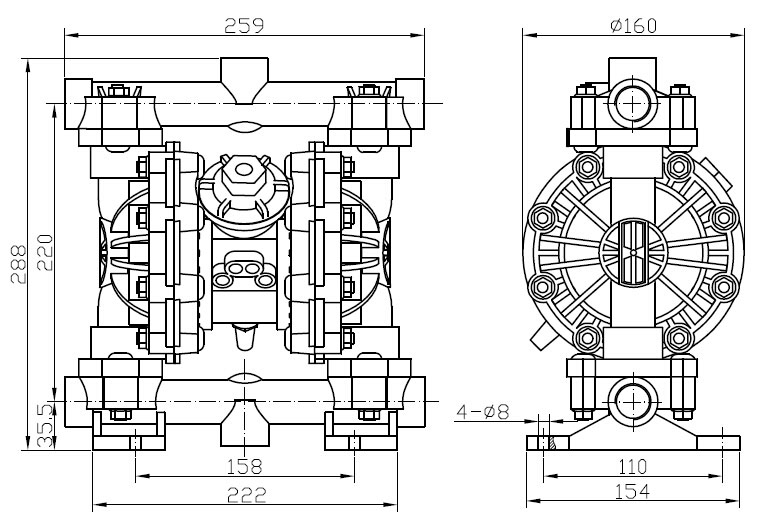

Other Informations Technical Specifications

| TECHNICAL SPECIFICATIONS | |

| Fluid connection | 1/4″ BSP |

| Air connection | 4 mm |

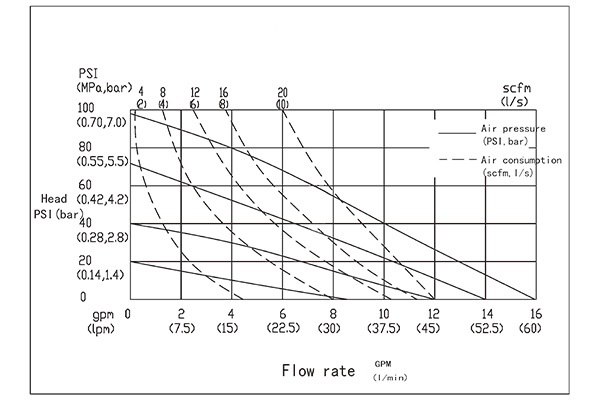

| Max flow-rate* | 8 l/min |

| Max air pressure | 6 bar |

| Max delivery head* | 60 m |

| Max Suction Lift Dry* | 3 m |

| Max Suction Lift Wet* | 9,8 m |

| Max Solid passing | 2 mm |

| Noise level | 62 dB |

| Max Viscosity | 5.000 mPas |

| Material | PP/PVDF+CF/POMc |

| Displacement per Stroke | 18 cm³ |

| * Depending on the materials All threads are internal threads All values mentioned are non-binding guide values | |

- Our AODD pump is portable and easy to assemble. Simple controls allow for easy installation and usage.

- The design of the pump enables a high suction lift with the self-priming feature.

- The compatible exterior components of an AODD pump make it easy to operate while submerged in the liquid.

- A simple change in the air supply allows our AODD pumps to operate at flow and discharge pressures as high as 120 psi!

- The pump has no close-fitting or spinning elements, making it easy to move liquids with a high solids concentration.

Request a Quote

Fill all information details to consult with us to get sevices from us

WhatsApp us