Smart Solutions for Clearer Water: Inside Coagulant & Flocculant Dosing

Water treatment is essential for ensuring clean water for human consumption and industrial usage. Among the essential steps are coagulation and flocculation, and two chemical dosing methods remove particles, color, and contaminants from the water.

What is Coagulant and Flocculant Dosing?

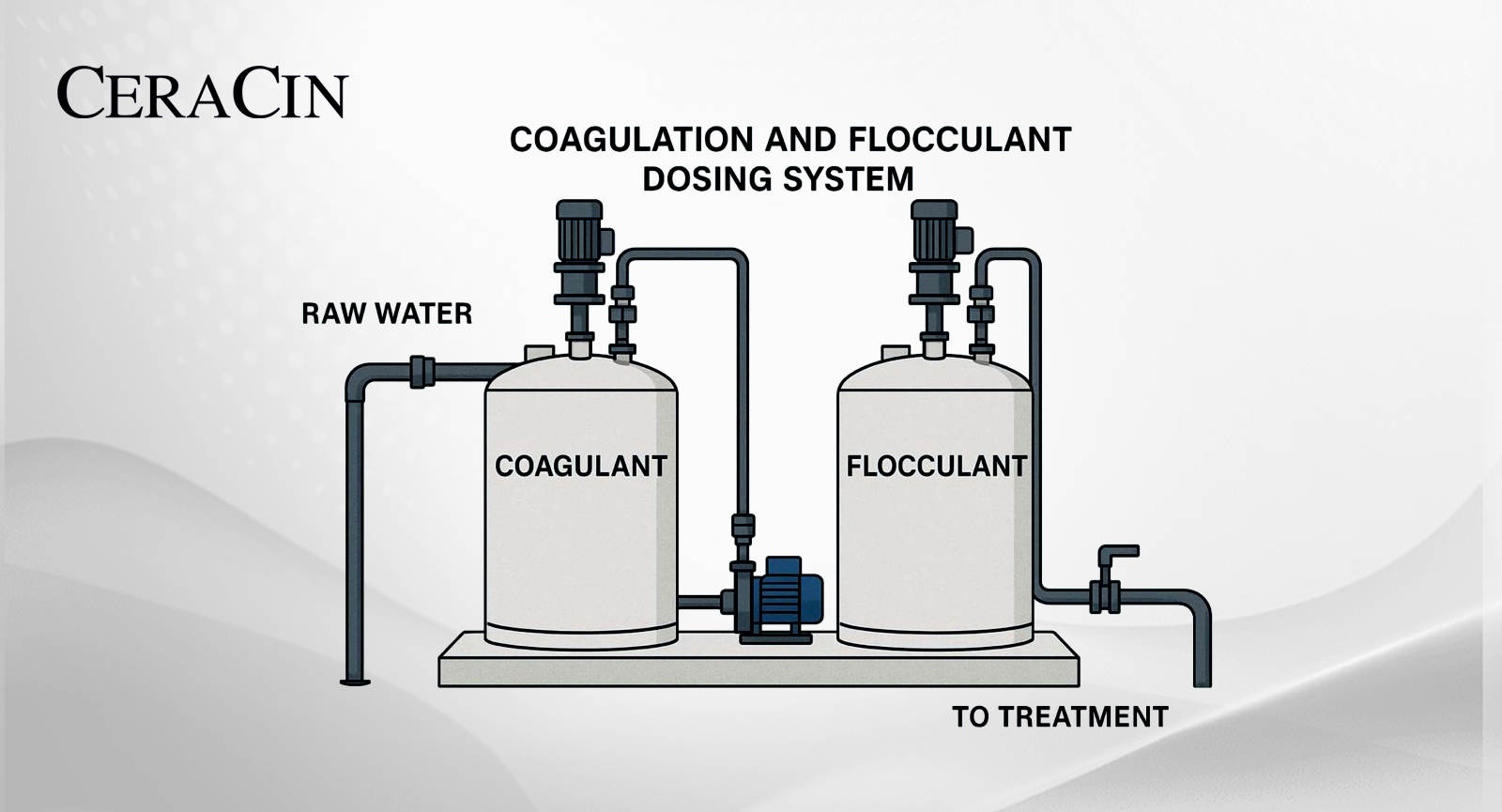

The dosing system in the industries allows automated chemical feed setup to do water treatment.

Coagulation and flocculation are often the paired steps in the water treatment process.

The process of coagulation involves adding chemicals (Coagulant) to the fluid to neutralize the suspended particles, such as slit and clay. Some of the chemicals used during this process are Alum (Al₂(SO₄)₃), Ferric Chloride (FeCl₃), and PAC (Poly Aluminium Chloride).

Once neutralized, these particles come together to form small clumps. After this process, another set of chemicals called flocculants (mostly Polyacrylamide, cationic) is added to the fluid to further aggregate the small clumps into the larger flocs, which can be removed through the sedimentation process.

Major Functions of Coagulant and Flocculant Dosing

Here are the major steps of Coagulant and Flocculant Dosing

- Preparation:

The machine safely stores the coagulant/flocculant chemicals. Mix powder or liquid into the correct dilution.

- Dosing:

Delivers the precise amount of chemicals using the dosing pump, depending on the flow rate or the turbidity sensors.

- Monitoring:

Use sensors for checking pH level and flow of the liquid, which controls the performance.

- Floc Formation:

Ensure ideal mixing and retention time to form large, settleable flocs.

- Sludge Reduction:

Assist the downstream system in reducing the solid content.

Advantages of Coagulant and Flocculant Dosing

- Economic:

The precision of the operations reduces chemical wastage and energy consumption, leading to a reduction in operational cost. It also safely stores the coagulant/flocculant chemicals.

- Eco-Friendly:

Overuse of the chemical can impact the quality of water and lead to resource waste. The dosing pump ensures that the chemical is used in the accurate amount, which not only reduces resource waste but also encourages sustainable practices.

- Improved Output:

By maintaining the accurate dosing level, the machine effectively removes all the contaminants.

The new dosing machines have advanced features like real-time monitoring, automated control, and data logging, which make the operations more efficient and accurate. The operators can optimize the operations by using these advanced features and troubleshooting any issues well in advance.

Applications of Coagulant and Flocculant Dosing

- Food & Beverage Processing:

It is used in the food processing industry to ensure that clean and contamination-free water is used, so that it does not impact health in any way.

- Mining:

It helps in tailing and reducing the water consumption.

- Pulp and Paper:

Enhances the reuse of water and discharge quality.

- Oil & Gas:

Treats the produced water and reduces the environmental impact.

Wrapping Up….

As digital technologies continue to evolve, the integration of AI has made machine learning and cloud-based systems for further enhancing the capabilities of smart dosing solutions. Some of the advanced models can also forecast the water quality changes, enabling proactive adjustments before the problem arises. If you, too, want to invest in a high-quality dosing pump offering precise output, then invest in the most reliable manufacturers of dosing pump Ceracin. They offer the highest quality products in various designs and specifications. You can choose the one according to your requirements and see your business rise to new heights.

Ceracin

Ceracin has expertise in industrial pump manufacturing since 2016. We are committed to provide our nation with the highest quality pumps at competitive prices.