How Dosing Pumps Help Control pH Level in WTPs, ETPs, and STPs?

Our ecosystem requires water treatment plants to maintain ecological balance by purifying recovered water before it is returned to nature or reused. One of their primary roles is to regulate the pH level in water. To ensure effective treatment, a certain pH level that shows the acidity or alkalinity of the liquid must be maintained. Many sectors, such as Water Treatment Plants (WTP), Effluent Treatment Plants (ETP), and Sewage Treatment Plants (STP), use dosing pumps to maintain and balance pH levels.

This blog explains how dosing pumps help balance pH levels in ETPs, WTPs, and STPs.

What is the pH?

pH refers to a substance’s hydrogen potential, or the number of hydrogen atoms in a solution. It is described using the pH scale, which ranges between 0 and 14. Acidic solutions have a pH of 0-6 (high concentration of hydrogen ions), whereas basic solutions have a pH of 8-14 (low concentration of hydrogen ions). A solution with a pH of 7, equivalent to pure water at 25°C, is considered normal.

- pH < 7 = Acidic

- pH = 7 = Neutral

- pH > 7 = Alkaline

Water/wastewater must usually be treated to fall within pH 6.5 to 8.5 before discharge or reuse. When treating industrial wastewater, pH management is critical for ensuring your operation runs smoothly and environmental rules are followed. Dosing pumps deliver chemicals to control and adjust the acidity or alkalinity of water or wastewater.

Chemicals used for pH adjustments

Different chemicals are used for pH correction depending on a number of circumstances, including whether the pH is already high or low. A single system may require an acidic and a basic buffer to keep the water within the appropriate range. This is to achieve the highest level of perfection attainable. The most frequent chemicals used to neutralize too basic water are sulphuric acid and sodium hydroxide.

Chemicals used to raise pH (make it less acidic) include:

- Sodium Hydroxide (NaOH)

- Calcium Hydroxide (Lime)

- Sodium Carbonate (Soda Ash)

Chemicals used to lower pH (make it less alkaline) are:

- Sulfuric Acid (H₂SO₄)

- Hydrochloric Acid (HCl)

- Alum (Aluminum Sulfate)

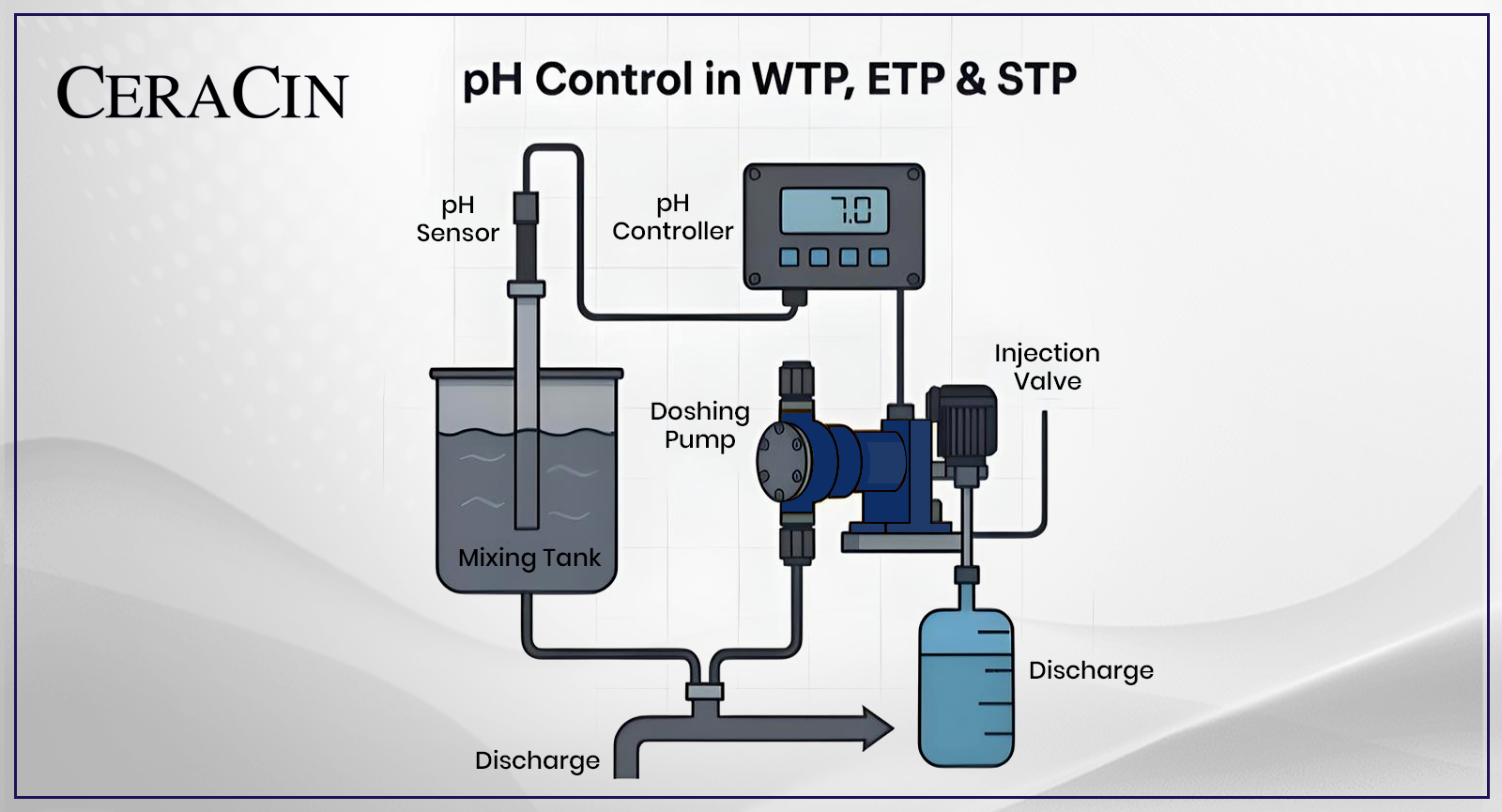

How does a Dosing Pump System Balance pH Levels?

A dosing pump injects the chemicals to adjust the pH level of water. If you want to raise the pH level, use sodium hydroxide and calcium hydroxide. Also, you can use sulfuric acid, hydrochloric acid, and alum to lower the pH level. These chemicals adjust the acidity and alkalinity of water.

Dosing systems monitor the pH level and automatically inject acidic or alkaline chemicals. This process is important in water treatment plants, sewage treatment plants, ETPs, and the pharmaceutical production industry.

Key Components of a pH Dosing System:

- pH Sensor: This sensor monitors and detects the pH of the solution.

- Control System: It receives pH sensor data and compares it with the required setpoint. It also controls the pump operation.

- Dosing Pump: It injects chemicals into the solution to balance the pH level.

- Chemical Reservoir: It stores the acid or alkaline chemical.

- Mixing System: In the mixing chamber or tank, chemicals are added or mixed with the solution.

- Final pH Check: This provides the final output and ensures water is within the allowable pH range.

Applications of Dosing Pumps in Different Treatment Plants

Water Treatment Plants (WTP)

pH is adjusted to protect pipelines and improve water quality for use.

Effluent Treatment Plants (ETP)

Industrial waste often has extreme pH values. Dosing systems neutralize the water before it goes through further treatment or is released. Common in industries like textiles, chemicals, pharmaceuticals, and food processing.

Sewage Treatment Plants (STP)

pH must be stable for bacteria that break down waste. Helps protect treatment microbes and plant equipment.

Final Words

In this blog, you learned about the importance of pH levels in different treatment plants and how dosing pumps help maintain this pH. Dosing systems keep pH within the right range and ensure water quality. This helps ETPs, STPs, and WTPs run their operations smoothly, cut operating costs, and ensure the safety of their workers and the environment.

Ceracin

Ceracin has expertise in industrial pump manufacturing since 2016. We are committed to provide our nation with the highest quality pumps at competitive prices.